Mei Levante

Category

Introduction

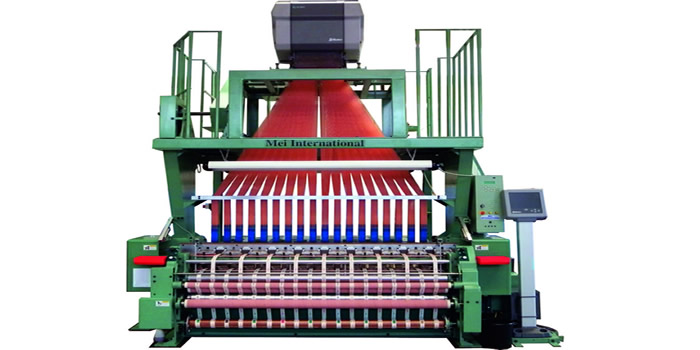

Our labels textile machines are available in a number of different versions. Depending on the intended end-use and fabric construction, you can choose between machines equipped with one single jacquard, taffetà or satin, rapier or airjet solution. Specialist machines are also available for producing ribbons and narrow fabrics with shuttle-loom and we also offer flexible mode looms, all-round jacquard machines.

Description

EXCELLENCE IN QUALITY WITH EASIER WAY TO MAINTAIN

MEI INTERNATIONAL: THE KEY TO SUCCESS IN LABEL WEAVING

Labels with softest selvedges with eco-friendly yarns. High productivity and quick responses of the machine; natural fibers insertion in easy way, without adjustments, with low strength, can also be used in this loom with result of new fashion labels and narrow fabrics design. This traditional weaving construction produces a woven substrate of a uniform architecture and thickness, across the entire width of the material with SOFT & UNIQUE knitted edges. Shuttle loom construction is superior and preferred for specific applications like underwear, tubular webbing for jeans, special ribbons for furniture and so on.

Characteristics

Overall dimension Height 3.600 mm. - lenght 3.900 mm. - width 2.200 mm.

Speed Up to 150 rpm. max

Large bobbins can move through small shedding

Large bobbins can move through small shedding

Because of a jacquard with dowel and inclining shedding motion, large bobbins can be used and an operation

more convenient.

Less friction between warp ands and shuttles, enables you using natural fiber and other low-strength yarn.

Controller combined Jacquard and loom for a perfect efficiency

Electronic Jacquard Staubli with controller JC7 for en efficient and easy working system compatible

with available files type and system for a better textile patterns standard format of jacquard witer

448 or 896 hooks.

Large bobbins can move through small shedding

Because of a jacquard with dowel and inclining shedding motion, large bobbins can be used and an operation

more convenient.

Less friction between warp ands and shuttles, enables you using natural fiber and other low-strength yarn.